ACCELERATING CHANGE THROUGH LEAN GREENBELT

back

CHANGE FOR THE BETTER AT DUXTON

Duxton Windows is a window and door manufacturer and the brainchild of Al Dueck; an entrepreneur who envisioned a family business as a means to build a brand with longevity. Dueck wanted to use innovative products to create hometown jobs and pass a legacy on to the next generation.

As a manufacturer of high-quality fiberglass products, Duxton serves light commercial and residential markets across the prairies, into the far north and the United States. The company maintains a three-part focus on energy efficiency, durability and design responsiveness. At Duxton, management believes in leading with heart and helping people grow their careers.

Fulfilling their founding vision of creating jobs and opportunities for Manitobans, the company makes every effort to promote and grow employees from within. From the shop floor, to lead hands, to management and beyond – Duxton is passionate about people.

THE POWER OF PEOPLE

But with the pressures facing Canadian manufacturers in today’s market, it’s not enough to bring passionate people on board. To go further and compete on a world-stage, every part of the organization needs to align to a single true north.

For Duxton, this meant eliminating the barriers that were holding the company back from achieving its long-term vision. Production constraints, disorganization on the shop floor, over processing and rework all had expensive consequences. Following the Toyota Way was all well and good, but how to get started?

At Duxton, the journey started small. Initially, the company experimented by sending a few key employees to Lean Level I Yellowbelt training.

Soon after, little changes began happening on a daily basis – and adding up to big results. The company was hooked. But a bigger commitment was needed to create a culture of change and sustain improvements. That’s when Duxton decided to pursue the Greenbelt program.

With Greenbelts on staff, the company would have the right people in the right places with the right skills to effectively lead continuous improvement activities, deliver training and facilitate rapid improvement projects within their own organization.

A CULTURE OF CHANGE

Greenbelt training helped guide the company toward more strategic plant layout decisions and equipment purchases. Duxton’s team found the most value in the real-life applications, not just training simulations. Most notable about the transformation was the impact of educating plant floor staff and motivating them to embrace change.

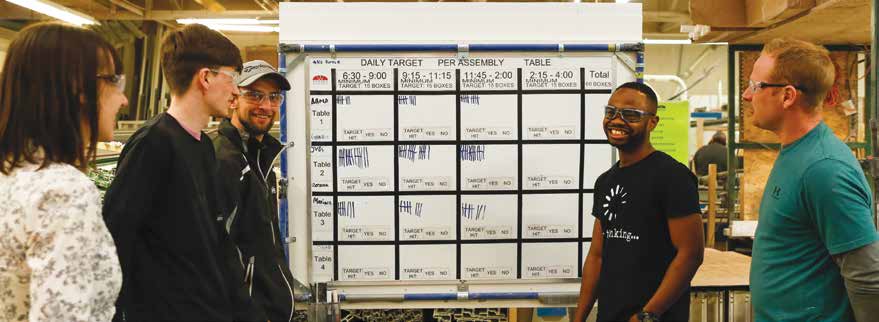

A visual system of daily targets on the floor ensures that everyone, no matter what role, understands how their work impacts the bigger company performance and mission. Staff are now trained to pull together in the same direction, with clear messages that help align everyone in the organization.

And that’s not all. Through the Greenbelt initiative, Duxton created a culture of transformation; empowering every employee to own change. Every day, every department dedicates at least 15 minutes to rapid improvements, which is paying big dividends.

Scheduling a Gemba walk once a month allows employees the chance to showcase their improvements to management and explain their work procedures. Staff are incredibly proud of what they have accomplished and have the visual management tools to embrace metrics related to big picture vision while at the same time, communicating progress up and out. The department with the best monthly improvements is treated to a free lunch; a healthy competition that feeds back into a culture of continuous improvement.

The Greenbelt program impacted the internal culture at Duxton, but the changes are readily visible to outsiders as well. Customers and suppliers who walk through the factory regularly remark on the difference from previous visits; including new plant layout, better organization of tools and supplies at point of use, more efficient cell design and flow and much more.

ACCESS TO EXPERTS

Perhaps most importantly, Duxton has been able to rely on the experts at CME; both as facilitators during Greenbelt training (CME trainers are either Lean Blackbelts, or Master Blackbelts with decades of industry experience) and afterward, through coaching and consortium participation.

Ask anyone at Duxton and they’ll tell you that the biggest benefit of the Greenbelt program has been a daily commitment to change for the better. At 365 improvements per year, for the past three years – more than 1,000 step improvements have been made on the journey towards ideal state. Lean programs taught Duxton how to properly measure cycle times, and how to think about TAKT time and create a better rhythm through the plant to reduce work in process. Cycle times have been reduced by more than 20 per cent. Greenbelts on staff have also organized company-wide in-house Lean 101 training for staff, which is poised to make a big impact.

It can be daunting for growing organizations to step back and invest in change while at the same time navigating the complexities of today’s manufacturing world. But you don’t have to go it alone – CME experts are here to help. With programs designed by manufacturers, for manufacturers; CME has Lean and productivity supports tailored to different stages of the Lean journey.

Whether you’re just getting started, or are interested in accelerating your own productivity improvements, connect with CME’s team of Lean experts today and take advantage of the power of the network.

Original article at cme-mec.ca